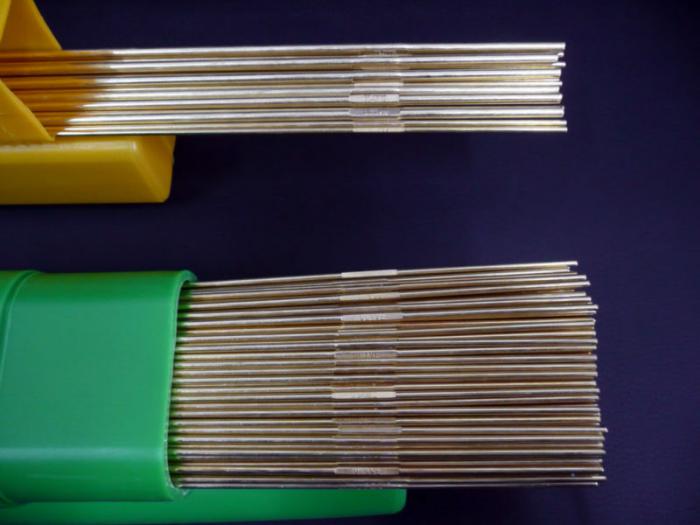

Alliage de cuivre BCuZn-C

Informations de base

Modèle: BCuZn-C

Description du produit

Longueur : 500 mm, 1000 mm

Métal : cuivre

Pont de marque : Permanent

Étain laiton, BCuZn-D, BCuZn-7, etc

Brasage du cuivre est en alliage de cuivre et de Zinc, employé couramment à souder en acier au carbone, en fonte, outils en carbure dur et ainsi de suite.

Nom de produit : Alliage de cuivre

Type :

Baguette de soudure :

Tige carrée et tige ronde

Carré taille : Max : 4,2 mm

: Ronde 5 mm ~10,0mm

Fil de soudure

Diamètre: 0. 6 mm ~ 1. 2 mm

Anneau de soudage

Diamètre de fil: 0. 8 mm ~ 1. 6 mm

Diameter(In) de l'anneau : 8mm ~ 35mm

| AWS |

Use expertise |

||||||||

| Numer | |||||||||

| BCuZn-2 | This model has good mobility and suits to the welding of the thick plate,copper,iron and copper alloy and this metal is quite gloosy after dissolved | ||||||||

| BCuZn-C | This model is suitable for the welding in high tensile strength, high temperature and good corrosion resistance. | ||||||||

|

Standard |

Chemical composition(%) |

Temperature |

|||||||

|

Cu |

Sn |

Mn |

Fe |

Zn |

Sodify |

Liquefy |

Use Temp. |

||

|

BCuZn-2 |

59-61 |

0.5-1.5 |

/ |

/ |

Rem |

890 |

905 |

900-955 |

|

|

BCuZn-C |

57-59 |

0.7-1.0 |

/ |

0.35-1.2 |

Rem |

920 |

930 |

930-980 |

|

|

AWS |

Use expertise |

||||||||

|

Numer |

|||||||||

| Copper Nicke(CuNi10) | Particularly suitable for the joining and overlay welding of copper nickel | ||||||||

| RBCuZn-D | It's suitable for surface corrosion resistance for cast steel,cast Iron,copper-alloy and nickel-alloy,as well as the joining welding of cast iron. | ||||||||

| CuZn40Ni | Most popular for padding material of Gas-welding and ARC welding in brass. Can also used in gas welding of copper,stell,copper-nickel,cast tion and cemented carbide alloy tools incrustation. | ||||||||

| Aluminum Bronze (High Mn ) | Best for the overlay welding of iron-casting and non-alloy steel that especially need corrosion resistance.Also good for overlay welding of cast Iron and Non-alloy low alloy steel that requires corrosion resisitance. | ||||||||

| Aluminum Bronze (High Ni) | Particularly suitable for welding casting and forging products of Cu-Al-Ni material such as propellers,bearing weights,valves,pumps and pipe systerms. Very good corrosion resisitance to seawater. | ||||||||

| Aluminum (Ni) Bronze | Recommended for the joining and overlaying of copper-aluminum alloys,aluminum coated steel in machinery and chemical industry as well as for Iron welding in shipbuilding.Also excellent for the join welding of brass tube and copper-aluminum that requires resisitance to erosion. | ||||||||

| AWS A5.7 ERCuAl-A3 | Particularly suitable for the joining and overlay welding of copper-aluminum alloys,sluminum coated steel,and cast Iron. | ||||||||

| AWS A5.7 ERCuAl-A2 | Particulary suitable for the overlay welding of copper,aluminum,and nickel materials with steel,it has incsisitance to ware and abrasion,as well as superior corrosion resisitance to seawater. Widely used for ship constructions,apparatus and plumbing.For multilayer welding on steel,pulsed ARC welding is recommended. | ||||||||

| AWS A5.7 ERCuAl-A1 | Perfect for joining welding of pure and austenitic steel sheet.Maintains good temperament flow and creates seamless welding line,Suggested for the joining welding of copper with steel,particularly suitable for machinery and shipbuilding industry.Pulesd ARC welding is recommended for multilayer on steel. | ||||||||

| AWS A5.7 ERCuSn; ERCuSn-A | Recommended for the joining welding of copper with CU-Sn alloy.Best for the joining welding of Cu-Zn alloy with steel.Pre-heart suggested for the large size products and pulsed ARC welding is recommended for multilayer on steel. | ||||||||

| AWS 5.7 ERCuSi-A | Recommended for the joining welding of copper with CU-Sn alloy.Best for the joining welding of Cu-Zn alloy with steel.Pre-heart suggested for the large size products and pulsed ARC welding is recommended for multilayer on steel. | ||||||||

| Red Brass | Has extremely high endurance and corrosion resistance.Suitable as mining cable for explosives in geological exploration. | ||||||||

| AWS 5.7 ERCuSi-A | Best for the joining and overlay welding of Cu-Zn alloy,especially for the MIG welding of Zinc coated steel sheet. Pre-heat suggested when MIG overlay welding for large size products and use pulsed ARC welding while overlay the steeel. | ||||||||

| AWS 5.7 ERCu | Specifically recommended for the ARC welding of copper and joining welding of copper with steel,cast iron and nickel alloys.Best for large components. | ||||||||

| Silver Copper (CuAg1) | Particularly desired for MIG welding of Zinc-coated-steel in auto bodies.It is also recommended for CU-Zn alloy,low-alloy copper,non-alloys and low-alloys steel and cast iron.An materianl for making auto bodies. | ||||||||

| Copper Nickel (AWS 5.7 ERCuNi) | Especially good for seawater corrosion resisitance.Particularly suitable for the joining and overlay welding or copper nickel such as machinery,desalting of seawater,ship-building,Oil refinery,and food processing industries.Also suitable for welding of nonferrous alloys,dissmilar steel materials. | ||||||||

Groupes de Produits : Alliage de brasage